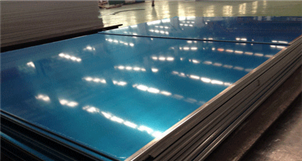

5052 Aluminium sheet

5052 aluminium sheet is Al-Mg alloy aluminium sheet. Magnesium is the main alloy element in 5052 alloy aluminium sheet. It is the most widely used rust-proof aluminium. This kind of alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in Semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, good weldability and poor machinability. It can be polished.

Aluminum-magnesium alloys also contain a small amount of manganese, chromium, beryllium, titanium and so on. In addition to a small amount of solid solution, most of the manganese in the alloy forms MnAl6. The effect of chromium in 5052 aluminium sheet is similar to that of manganese, which improves the stress corrosion cracking resistance, increases the strength of base metal and weld, and reduces the tendency of welding crack, but its content generally does not exceed 0.35%.

1) Introduction:

Material Name: Aluminum and Aluminum Alloy Extruded Bar (<150mm, H112, T6, O) Standard: GB/T3880-2006 Characteristics and Application Range: 1. 5052 belongs to Al-Mg alloy, which is widely used, especially in the construction industry. It is the most promising alloy. It has good corrosion resistance, good weldability, good cold workability and medium strength.

The main alloy element of 5052 is magnesium, which has good formability, corrosion resistance, weldability and medium strength. It is used to manufacture aircraft fuel tank, fuel pipe, sheet metal parts of traffic vehicles and ships, meters, street lamp brackets and rivets, hardware products, electrical-appliance shell, etc. (2) Al-Mn alloy is a kind of rust-proof aluminium which is widely used. This kind of alloy has high strength, especially fatigue strength: high plasticity and corrosion resistance, can not be strengthened by heat treatment, good plasticity in Semi-cold hardening, low plasticity in cold hardening, good corrosion resistance, good weldability, poor machinability and polishing. Uses are mainly used for low-load parts which require high plasticity and good weldability and work in liquid or gas media, such as oil tank, gasoline or lubricant conduit, various liquid containers and other low-load parts made by deep drawing: wire rods are used as rivets.

2) Chemical constituents:

Al :allowance ;

Si :0.25;

Cu :0.10 ;

Mg:2.2~2.8;

Zn:0.10;

Mn:0.10;

Cr:0.15~0.35 ;

Fe: 0.4 0

3)Mechanical property:

Tensile Strength (σb): 170-305 MPa

CONDITIONAL YIELD STRENGTH_0.2(MPa)>65

Modulus of Elasticity (E): 69.3-70.7 Gpa

The annealing temperature is 345 C.

4 ) Surface quantity:

1. No cracks, corrosion spots and nitrate marks are allowed on the surface.

2. Skin, bubbles, surface roughness and local mechanical damage are allowed on the surface with a depth not exceeding 8% of the nominal size of the defect, but the maximum depth of the defect can not exceed 0.5mm, and the total area of the defect can not exceed 5% of the total area of the plate.

3. The supplier is allowed to polish the profile lengthwise until the surface is smooth.

4. Other requirements: Demanders and suppliers make their own decisions.

5 ) Type of Welding Electrode:

5052 aluminium sheet can be welded with ER5356 electrode, and the mechanical properties of 5052 aluminium sheet can be satisfied after welding. Chemical constituents of 5356: Si: 0.25; Fe: 0.40; Cu: 0.10; Mn: 0.05-0.20; Mg: 4.5-5.6; Cu: 0.02-0.20; Zn: 0.10-0.20; Ti: 0.06-0.20; Al: remainder; 5336 contains a higher magnesium content.

1、 Hardness:

Hardness: Tensile strength of 1060 aluminium sheet is 110-130, while tensile strength of 5052 series is 210-230, that is to say, the hardness of 5052 is 100% higher than that of 1060.

Elongation: The elongation of 1060 series is 5%, while the elongation of 5052 series is 12-20%. It can also be considered that the elongation of 5052 series is increased by about 200% when it is 100% harder than 1060 series.

Chemical properties: 1060 is pure aluminium plate, 5052 is alloy aluminium plate, corrosion resistance of 5052 in special environment is better.

2、 Standard:

The national standard for aluminium sheet and strip (GB/T 3880-2006) is applicable to the unified standard for aluminium alloy sheet and strip materials.